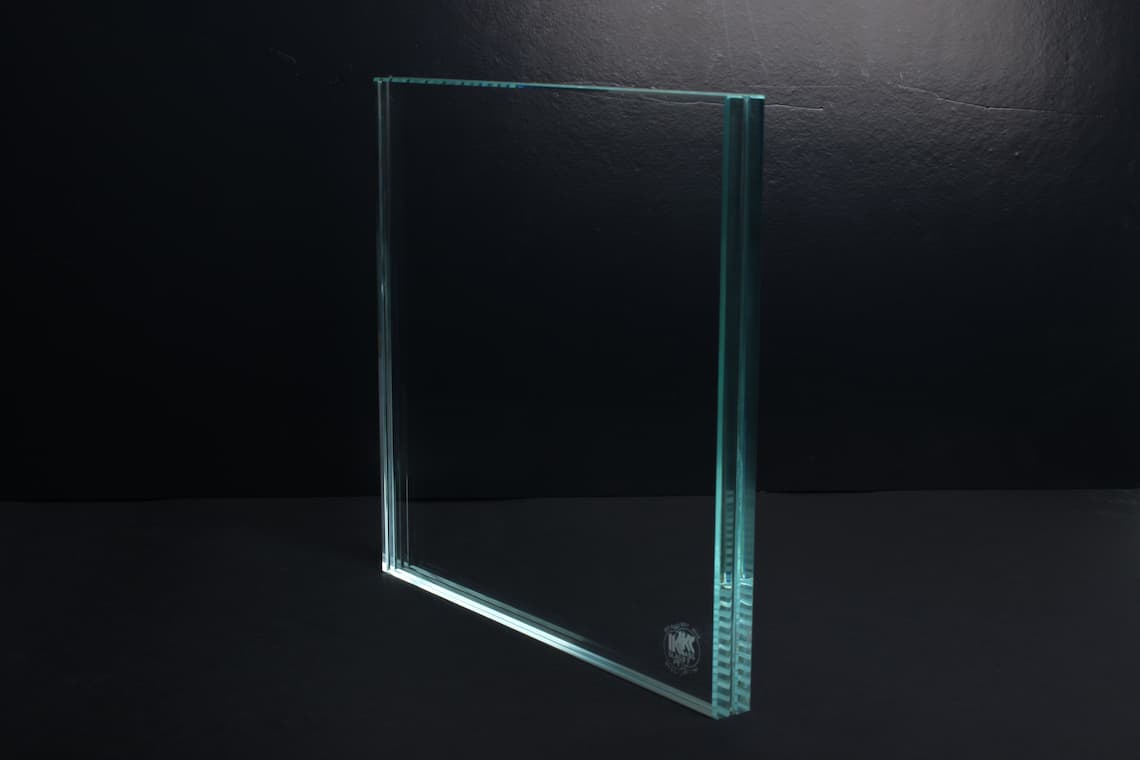

Laminated Glass

Description

Laminated glass is made up of one, two, or more layers of joined glass placed between layers of polyvinyl butyral (PVB), which are then heated and pressed together. The interlayer holds and supports the glass, acting as a solid and even layer in the event of shattering.

Features & Types

• Security: A perfect choice where high security is required, as the strength of laminated glass makes it difficult to break, and in case of breakage the interlayer holds the structure to prevent widening the gap easily.

• Safety: Suitable where sufficient strength is required to resist stress caused by different weather conditions. In case of breakage, the glass breaks into large pieces, remains in the original place and does not fall.

• Acoustic Insulation: Laminated glass blocks sound waves as they travel through the interlayer material, reducing external noise pollution.

• Energy Efficiency: Low-emissivity glass reduces the amount of heat or cool that is transferred to the space, resulting in less frequent use of the HVAC system and a decrease in emissions.

Types of Interlayers

IKK Laminated Glass is processed in various thicknesses and available in Annealed, Heat Strengthened, and Fully Tempered glass with:

• Clear PVB Interlayer

• Translucent PVB Interlayer

• Acoustic PVB Interlayer

• White PVB Interlayer

• Strong SGP Interlayer

• LED Interlayer

• Sentry glass

Applications

• Glass Floors

• Skylights

• Glass Roofs

• Glass Stairs

• Display cabinets

• Windows subjected to high risk of breakage

• Skylights

• Glass Roofs

• Glass Stairs

• Display cabinets

• Windows subjected to high risk of breakage